PipingProjects.eu is one of the leading Tie Rods Manufacturer in Europe. With an emphasis on precise engineering and exceptional quality, we provide a broad variety of Tie Rods that are designed to satisfy the various demands of industries throughout the continent. We use strict quality control procedures throughout the production process as a reliable Tie Rods Supplier in Europe to ensure that our goods constantly meet or surpass industry requirements. Our extensive selection of Tie Rods, which also include bolts, nuts, screws, and washers, are expertly crafted to provide outstanding corrosion resistance, lifespan, and dimensional accuracy.

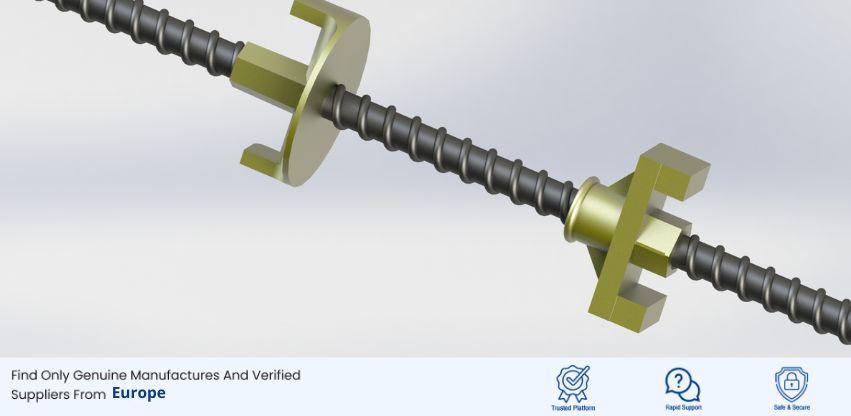

Tie Rods are structural elements primarily employed in engineering and construction contexts to support and stabilize a variety of constructions, such as cars, buildings, and bridges. These rods are usually long, cylindrical bars having threaded ends that may be connected to nuts or other fastening elements. The bars can be composed of steel or aluminium.

Tie Rods are frequently used to successfully preserve the integrity and stability of the overall structure by resisting tensile pressures and preventing the separation or movement of structural parts. Tie Rods are vital components in many engineering and construction projects because they distribute loads and stresses equally, which is especially important in situations where lateral movement or structural deformation needs to be avoided.

Selecting us as your dependable Tie Rods Manufacturer in Europe has several benefits because of our dedication to excellence, innovation, and client happiness. First and foremost, we place a high value on precise engineering and maintain strict quality control guidelines throughout the production process. Our cutting-edge facilities use high-tech and expert artistry to make Tie Rods that meet or surpass industry standards and legal requirements. As a well-known Tie Rods Supplier in Europe, we provide a wide selection of Tie Rods specifically designed to fit a range of uses and sectors, such as infrastructure, aircraft, automotive, and construction. Our adaptable solutions can meet each client's specific demands and guarantee excellent performance, robustness, and dependability even in the most challenging settings. We are a reputable company with a record of providing top-notch Tie Rods and outstanding customer service.

Trusted

Supplier

Genuine

Product

Easy

purchase

Tie Rods Specification Chart

PipingProjects.eu is a top Tie Rods Manufacturer in Europe, offers a wide variety of Tie Rods in different specifications to fit different sizes and grades.

| Fateners size | Specifications |

|---|---|

| Tie Rods Length | 1mtr to 3mtr |

| Metric Sizes | M1.6 - M48 |

| Imperial Size | 5/16" to 18" |

| Temperature Range | -40 to +80°C |

| Thread Types | Metric, Metric course, UNF, Metric Fine, BA, BSF, UNC, UNB, BSW |

| Process | Cold Rolled, Hot Rolled |

| Sizes | 6mm, 8mm, 10mm, 12mm, 16mm, 18mm, 20mm, 22mm, 30mm, 32mm, 36mm, 38mm, 39mm, 33mm, 40mm, etc |

| DIN Standard | 1993-5 |

| Grade | |

| Stainless Steel | 200 Series - 201, 202, 205.

300 Series 301, 302, 303, 304, 304L, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316TI, 317, 317L, 321, 347. 400 Series 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414,416, 416Se, 420,420F, 422, 431, 440A, 440B, 440C. 500 Series - 501, 502. 600 Series - 630 (17-4 PH). |

| Titanium | Titanium 6-4, Gr 1, Gr 2, Gr 3, Gr 4, Gr 5, Gr 7, Gr 9, 5-2.5, 6-2-4-2, 6-4 ELI, 6-6-2. |

| Hastelloy | C22, C276, X, B-2. |

| Monel | 400, K500. |

| Nickel Alloy | Nickel 200 Nickel 201, Alloy 20, Alloy 286, Alloy 218 (Nitronic 60), Nitronic 50 (XM-19). |

| Cupro Nickel | Cu 90-10 (C70600,CW352H), Cu 70-30 (C71500, CW354H). |

| Inconel | 601, 625, 660A, 718, X-750, 825, 925, 608. |

| Duplex / Super Duplex | D S31803, D S32205, SD S32750, SD S32760, SD S32950. |

| Chromium Molybdenum Steel | A387 Gr 2, A387 Gr 12, A387 Gr 11, A387 Gr 22, A387 Gr 22L, A387 Gr 7, A387 Gr 21, A387 Gr 21L, A387 Gr 9, A387 Gr 91. |

| Nichrome Alloy | CrNi 20/80. |

| Copper | ASTM B1, ASTM B2, ASTM B3, ASTM B152, ASTM B124, ASTM B133. |

| Brass | Alloy 260, Alloy 272, Alloy 330, Alloy 353, Alloy 360, Alloy C48200 - C48500, Alloy 464. |

| Bronze | Alloy 954, Alloy 933. |

| Case Hardening Steels | 10C4, 15C8, 15Cr3, 16Mn5Cr4, 20MnCr5, 15Ni5Cr4Mo1, 15Ni5Cr4Mo2, 20Ni7Mo2, 20NiCrMo2, 14CrNi6. |

| En Series | En8, En9, En19, En24, En30B, En31, En36, En45, En47, En48. |

| Mild Steel | Sae 4118, Sae 4120, Sae 4120, Sae 4130, Sae 4135, Sae 4137, Sae 4140, Sae 4142, Sae 4145, Sae 4147, Sae 4150, Sae 4161, Sae 8620. |

Which industries commomly use Tie Rods?

Tie Rods Chemical Composition

As a top Tie Rods Supplier in Europe, we offer Tie Rods made from premium steel alloys with exact chemical compositions, such as regulated amounts of silicon, sulfur, phosphorus, and carbon, guaranteeing the best mechanical qualities and dependability for a range of industrial uses.

| Element | Percentage Composition |

|---|---|

| Carbon | 0.12% - 0.25% |

| Manganese | 0.60% - 0.90% |

| Phosphorus | 0.04% maximum |

| Sulfur | 0.05% maximum |

| Silicon | 0.15% - 0.35% |

| Iron | Balance (remainder of composition) |

how to prevent Tie Rods from rusting or corrosion

Tie Rods Mechanical Properties

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength | 400 - 800 MPa |

| Yield Strength | 250 - 600 MPa |

| Hardness | 150 - 250 HB |

| Ductility | 10% - 25% elongation |

| Fatigue Resistance | High |

As a trusted Tie Rods Manufacturers in Europe, These are just a few of the many industrial needs that our extensive assortment of Tie Rods may meet.

Tie Rods Dimension Chart

| Thread Size | ©D (mm) | Weight (kg/m) | Grade 460 | Grade 500 | Grade | 550 | Grade | 650 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| YL(Kn) | UL(Kn) | YL(Kn) | UL(Kn) | YL(Kn) | UL(Kn) | YL(Kn) | UL(Kn) | |||

| M48x5 | 40 | 9.86 | 578 | 767 | 628 | 817 | 691 | 942 | 817 | 1068 |

| M56x5.5 | 45 | 12.48 | 732 | 970 | 795 | 1034 | 875 | 1193 | 1034 | 1352 |

| M60x5.5 | 50 | 15.41 | 903 | 1198 | 982 | 1276 | 1080 | 1473 | 1276 | 1669 |

| M68x6 | 55 | 18.65 | 1093 | 1449 | 1188 | 1544 | 1307 | 1782 | 1544 | 2019 |

| M72x6 | 60 | 22.2 | 1301 | 1725 | 1414 | 1838 | 1555 | 2121 | 1838 | 2403 |

| M76x6 | 65 | 26.05 | 1526 | 2024 | 1659 | 2157 | 1825 | 2489 | 2157 | 2821 |

| M85x6 | 70 | 30.21 | 1770 | 2348 | 1924 | 2501 | 2117 | 2886 | 2501 | 3271 |

| M90x6 | 75 | 34.68 | 2032 | 2695 | 2209 | 2872 | 2430 | 3313 | 2872 | 3755 |

| M95x6 | 80 | 39.46 | 2312 | 3066 | 2513 | 3267 | 2765 | 3770 | 3267 | 4273 |

| M100x6 | 85 | 44.54 | 2610 | 3461 | 2837 | 3688 | 3121 | 4256 | 3688 | 4823 |

| M105x6 | 90 | 49.94 | 2926 | 3881 | 3181 | 4235 | 3499 | 4771 | 4135 | 5407 |

| M110x6 | 95 | 55.64 | 3261 | 4324 | 3544 | 4607 | 3899 | 5316 | 4607 | 6025 |

| M115x6 | 100 | 61.65 | 3613 | 4791 | 3927 | 5105 | 4320 | 5890 | 5105 | 6676 |

| M125x10 | 105 | 67.97 | 3983 | 5282 | 4330 | 5628 | 4762 | 6494 | 5628 | 7360 |

| M135x10 | 115 | 81.54 | 4778 | 6336 | 5193 | 6751 | 5713 | 7790 | 6751 | 8829 |

| M140x10 | 120 | 88.78 | 5202 | 6899 | 5655 | 7351 | 6220 | 4882 | 7351 | 9613 |

| M150x12 | 125 | 96.33 | 5645 | 7486 | 6136 | 7977 | 6750 | 9204 | 7977 | 10431 |

manufacturing process of Tie Rod

Front Inner Tie Rod Size Chart

| Front Inner Tie Rods Size Chart | ||||

|---|---|---|---|---|

| 060 | 1/2" | 12FT | 6.4 | 9,000 |

| 061 | 3/4" | 12FT | 13.4 | 18,000 |

| 062 | 7/8" | 12FT | 20.04 | 31,000 |

| 063 | 1" | 12FT | 24.48 | 38,000 |

| 064 | 1-1/4" | 12FT | 41.76 | 56,000 |

| 065 | 1-1/2" | 12FT | 72.12 | 68,000 |

| 066 | 1/2" | 6FT | 53 | 9,000 |

| 067 | 3/4" | 6FT | 118 | 18,000 |

| 068 | 1" | 6FT | 210 | 38,000 |

| 069 | 1-1/4" | 6FT | 340 | 56,000 |

What are the potential causes of Tie Rod failure?

Tie Rod Weight Chart

| Size (MM) | Weight per Metre | Size (UNC) | Weight per Mtr |

|---|---|---|---|

| M2 | 0.0187 | ||

| M2.5 | 0.030 | ||

| M3 | 0.044 | ||

| M3.5 | 0.060 | ||

| M4 | 0.078 | ||

| M5 | 0.124 | ||

| M6 | 0.177 | 1/4" | 0.194 |

| M8 | 0.319 | 5/16" | 0.323 |

| M10 | 0.500 | 3/8" | 0.469 |

| 7/16" | 0.650 | ||

| M12 | 0.725 | 1/2 | 0.896 |

| M14 | 0.970 | 9/16" | 1.096 |

| M16 | 1,330 | 5/8" | 1.342 |

| M18 | 1.650 | ||

| M20 | 2.080 | 3/2 | 2.021 |

| M22 | 2.540 | 7/8" | 2.756 |

| M24 | 3.000 | 1" | 3.638 |

| M27 | 3.850 | 1 1/8" | 4.545 |

| M30 | 4.750 | 1 1/4" | 5.718 |

| M33 | 5.900 | 1 3/8" | 6,842 |

| M36 | 6.900 | 1 1/2" | 8.281 |

| M39 | 8,200 | 1 5/8" | 9.726 |

| M42 | 9,400 | 1 3/4" | 11.231 |

| M45 | 11.000 | 17/8" | 13.038 |

| M48 | 12,400 | 2 | 14.741 |

Most Common Uses for Tie Rods

Tie Rods Manufacturer in Europe

Tie Rods Supplier in Europe