Steel Pipe Manufacturer, Supplier & Exporter in Portugal - PipingProjects.eu

PipingProjects.eu is one of the leading Steel Pipe Manufacturer in Portugal. We guarantee excellent steel pipes that satisfy any project need. Our primary objectives as a reliable Steel Pipe Supplier in Portugal are accurate engineering, strict quality control, and timely delivery to guarantee exceptional performance and satisfied clients. As a reputable and trustworthy company, we want to gain your trust and become your first option for any steel pipe needs in Portugal and the neighboring territories.

What are Steel Pipes?

Steel Pipes are cylinders that are mostly made of steel and are extensively utilized in many different industries because of their durability, strength, and flexibility. They have several applications in plumbing, manufacturing, construction, and infrastructure. They also serve as conduits for the movement of gases and fluids and sustain structural frameworks. Steel pipes come in a variety of sizes, shapes, and grades, including seamless and welded configurations, to accommodate a wide range of uses. They offer affordable solutions for the long-distance movement of solids, gases, and liquids. They also exhibit exceptional resistance to corrosion and have a high temperature and pressure tolerance. Steel pipes are essential components of modern industrial processes and infrastructure because they are dependable, strong, and efficient. Whether they are utilized in oil and gas pipelines, water distribution networks, or structural frameworks.

Top leading Manufacturing Companies

What is the Purpose of Steel Pipe?

- Steel Pipes are primarily designed to ensure efficient and reliable transportation of fluids, gases, and solids from one location to another. These versatile conduits play a crucial role in a wide range of industries and applications. In the domain of fluid transport, steel pipes are essential for conveying liquids like water, oil, natural gas, and chemicals.

- Steel Pipes have a pivotal role in supplying clean water to urban areas, distributing natural gas for heating and energy production, and carrying oil from drilling sites to refineries. Apart from fluid transport, steel pipes also serve as essential structural components in construction and civil engineering, providing strength and stability to buildings, bridges, and other structures.

- Steel Pipes have a crucial role in fluid transportation, serving a vast range of industries and applications. They are used in plumbing systems, industrial applications, power plants, and infrastructure projects, facilitating the efficient flow and distribution of essential resources. Steel Pipes offer remarkable strength and structural integrity, making them suitable for carrying heavy loads and withstanding high pressures. Overall, steel pipes are indispensable conduits for reliable and efficient transportation of fluids, gases, and solids.

Steel Pipe

Steel Pipe - Specifications

- Product : Steel Pipe

- Size : 1/8" to 48"

- Method : Hot Rolled & Cold Rolled

- Austenitic Steel : 301, 304, 304 H, 304 L, 310, 310,316, 316 L, 317, 317 L, 321, 347

- Ferritic Steel : 409, 409 M, 410 S, 420, 430

- Schedule : ASTM, ASME B36.10, ASME B36.19, ASME B36.10M, ASME B36.19M, BS EN 10204

Trusted

Supplier

Genuine

Product

Easy

purchase

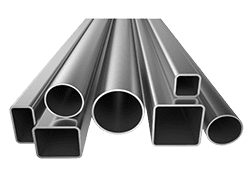

What is the Difference Between Steel Pipe & Tube?

- As per industry standards, steel pipes and steel tubes are designed for different applications based on their structural characteristics. Steel Pipes are primarily used for the transportation of fluids like oil, water, or gas, and need to adhere to stringent industry standards governed by organizations like ASTM (American Society for Testing and Materials) or API (American Petroleum Institute).

- Steel Pipes are known for their rigid and consistent, round cross-sectional shape, and are usually classified based on their nominal pipe size (NPS) or nominal outside diameter (OD). This makes them ideal for efficiently transporting a variety of liquids and gases.

- Steel tubes, on the other hand, are more versatile in their applications. Unlike pipes, tubes are designed to meet specific requirements beyond fluid transport and come in various shapes such as round, square, and rectangular. They also have standardized dimensions that encompass both the outside diameter (OD) and wall thickness.

Steel Pipe Specification, Size & Grades

PipingProjects.eu is a top Steel Pipe Manufacturer in Portugal, offers a wide range of products with different specifications to suit various sizes and grades.

Steel Pipe Specifications

| Specification |

Material Grade |

Size Range (NPS) |

Wall Thickness |

Application |

| ASTM A53 |

A, B |

1/8" - 26" |

Sch 10, 40, 80 |

General Purpose, Plumbing, HVAC |

| ASTM A106 |

A, B, C |

1/8" - 48" |

Sch 10, 20, 30, 40, 80, 160 |

High-Temperature Service |

| ASTM A333 |

1, 3, 6, 8 |

1/8" - 26" |

Sch 40, 80 |

Low-Temperature Service |

| ASTM A335 |

P1, P5, P9, P11, P12, P22, P91 |

1/8" - 26" |

Sch 10, 20, 30, 40, 80, 160 |

High-Temperature Service (Alloy Steel) |

| API 5L |

X42, X52, X60, X65, X70 |

1/8" - 60" |

Sch 10, 20, 30, 40, 80 |

Oil and Gas Transportation |

| ASTM A312 |

TP304, TP316, TP321 |

1/8" - 24" |

Sch 5, 10, 40, 80 |

High-Temperature and Corrosive Fluids (Stainless Steel) |

| ASTM A500 |

Grade A, B, C |

1/2" - 24" |

0.120" - 0.625" |

Structural and Mechanical Tubing |

| ASTM A554 |

TP304, TP316 |

1/2" - 12" |

0.035" - 0.500" |

Ornamental and Structural Tubing (Stainless Steel) |

| DIN 2440 |

St33 |

6mm - 150mm |

1mm - 5.4mm |

General Purpose |

Steel Pipe Size Chart

Steel Pipe Size Table

| Nominal Pipe Size |

ID |

OD |

WALL THICKNESS |

WEIGHT (LB/FT) |

| 1/2 |

0.622" |

0.840" |

0.109" |

0.85 lb/ft |

| 1/4 |

0.364 |

0.540' |

0.088" |

0.42 lb/ft |

| 1/8 |

0.269" |

0.405" |

0.068" |

0.24 lb/ft |

| 3/4 |

0.824" |

1.050" |

0.113" |

1.13 lb/ft |

| 3/8 |

0.493" |

0.675" |

0.091" |

0.57 lb/ft |

| 1 |

1.049" |

1.315" |

0.133" |

1.68 lb/ft |

| 1-1/2 |

1.610" |

1.900" |

0.145" |

2.72 lb/ft |

| 1-1/4 |

1.380" |

1.660" |

0.140" |

2.27 lb/ft |

| 2 |

2.067" |

2.375" |

0.154" |

3.65 lb/ft |

| 2-1/2 |

2.469" |

2.875" |

0.203 |

5.79 lb/ft |

| 3 |

3.068" |

3.500" |

0.216" |

7.58 lb/ft |

| 3-1/2 |

3.548" |

4.000" |

0.226" |

9.11 lb/ft |

| 4 |

4.026" |

4.500" |

0.237 |

10.79 lb/ft |

| 6 |

6.065" |

6.625" |

0.280" |

18.97 lb/ft |

| 5 |

5.047 |

5.563" |

0.258 |

14.62 lb/ft |

| 8 |

7.981" |

8.625" |

0.322" |

28.55 lb/ft |

| 12 |

11.938" |

12.75" |

0.406" |

53.52 lb/ft |

| 10 |

10.020" |

10.750 |

0.365 |

40.48 lb/ft |

| 14 |

13.124" |

14.000" |

0.438" |

63.50 lb/ft |

| 18 |

16.876" |

18,000" |

0.562" |

104.70 lb/ft |

| 16 |

15.000" |

16.000" |

0.500" |

82.77 lb/ft |

| 20 |

18.812" |

20,000" |

0.594" |

123.10 lb/ft |

| 24 |

22.624" |

24.000" |

0.688" |

171.30 lb/ft |

What is the Difference Between Schedule and Nominal Pipe Size (NPS)?

- Understanding the difference between "schedule" and "nominal pipe size (NPS)" is fundamental when it comes to steel pipes. NPS refers to the standardized size designation for a pipe based on its internal diameter, making it easier to identify pipes in specific size ranges. However, it doesn't represent the pipe's actual dimensions or wall thickness accurately. Schedule, on the other hand, refers to the thickness of the pipe's wall and is indicated by a schedule number such as Sch 40 or Sch 80.

- This schedule number defines the wall thickness and pressure-carrying capacity of the pipe. Pipes with higher schedule numbers have thicker walls and can handle greater pressure. Therefore, while NPS defines the pipe's nominal size, schedule is crucial for determining its strength and suitability for specific applications, particularly in industries where pressure resistance plays a critical role in selecting the appropriate steel pipe.

Chemical Composition of Steel Pipe

Chemical Composition of Steel Pipe

| Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

| 304 |

min. max. |

- 0.08 |

- 2.0 |

- 0.75 |

- 0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 10.5 |

- 0.10 |

| 304H |

min. max. |

0.04 0.10 |

- 2.0 |

- 0.75 |

-0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 10.5 |

- - |

Mechanical Properties of Steel Pipe

Steel Pipe Mechanical Properties

| Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

| Rockwell B (HR B) max |

Brinell (HB) max |

| 304 |

515 |

205 |

40 |

92 |

201 |

| 304H |

515 |

205 |

40 |

92 |

201 |

What is the Difference Between Hot Rolled and Cold Rolled Steel Pipe?

- The process used to manufacture sheets and plates can significantly impact the resulting material properties. Hot-rolling, which involves high-temperature processing, produces thicker sheets that exhibit a characteristic scale and reduced mechanical strength, making them suitable for applications like construction.

- On the other hand, cold-rolling, which is performed at room temperature, yields smoother sheets with precise thickness tolerances, superior surface quality, and increased strength, making them ideal for applications that require precision and aesthetic appeal, such as automotive panels and appliances.

Steel Pipe Equivalent Grades

Stainless Steel Pipe Equivalent Grades

| Material Type |

ASTM/ASME (USA) |

EN (European) |

DIN (Germany) |

BS (UK) |

JIS (Japan) |

ISO (International) |

| Carbon Steel |

A36 |

S235JR |

ST37-2 |

40A/B |

SS400 |

ISO 630-2 S235 |

|

304/304L |

1.4301/1.4307 |

X5CrNi18-10 |

304S15 |

SUS304 |

ISO 15510 X5CrNi18-10 |

|

316/316L |

1.4401/1.4404 |

X5CrNiMo17-12-2 |

316S31 |

SUS316 |

ISO 15510 X5CrNiMo17-12-2 |

| Aluminium |

6061 |

EN AW-6061 |

AlMg1SiCu |

H20 |

AA6061 |

ISO 6361 6061 |

| Copper |

C11000 |

Cu-ETP |

E-Cu58 |

C101 |

C1100 |

ISO 13388 Cu-ETP |

Various Types of Steel Pipe

PipingProjects.eu is a leading Steel Pipe Supplier in Portugal. These are a few examples of Steel Pipes you can find at Piping Projects in Portugal.

Advantages of Steel Pipe

- Steel Pipe materials are highly versatile, strong, and durable, making them a popular choice for various industries such as construction, automotive, and manufacturing. Due to their uniform and flat surface, they are suitable for precise applications. Materials like stainless steel and aluminum offer exceptional resistance to corrosion, making them even more valuable. Therefore, sheet and plate materials are indispensable components in a wide range of industrial and engineering applications.

- Furthermore, sheet and plate materials are highly cost-effective and sustainable. These materials are designed to use resources efficiently, resulting in less material waste during production, and ultimately reducing overall material costs. Their durability and longevity lead to longer service life for end-products, reducing maintenance and replacement expenses. Additionally, their recyclability makes them environmentally friendly, contributing to sustainable practices. In various industries such as architectural design, automotive manufacturing, or consumer electronics, sheet and plate materials are indispensable components in achieving both economic and eco-conscious objectives.

Production Process of Steel Pipe

Steel Pipe is produced in seven steps. It manufactures a wide range of shapes, goods, and parts, ranging from Steel Pipe and Coil.

- Step 1 : Raw Material Selection

To begin the process of creating stainless steel, raw materials such as iron ore and other elements including nickel, chromium, and molybdenum are carefully selected. The choice of alloying elements depends on the specific properties that the stainless steel is intended to possess.

- Step 2 : Smelting and Melting

Once the raw materials have been selected, they are smelted in a furnace to create a molten metal alloy. The composition of the alloy is closely monitored and controlled to achieve the desired grade of stainless steel.

- Step 3 : Forming

After the molten stainless steel has been produced, it is cast into different shapes and forms, depending on its intended use. The most common shapes include slabs, billets, blooms, or ingots.

- Step 4 : Primary & Secondary Steelmaking

The subsequent step is primary steelmaking, which can be accomplished through different methods such as the Basic Oxygen Furnace (BOF) or the Electric Arc Furnace (EAF). At this stage, impurities like carbon are eliminated to achieve the desired chemical composition.

- Step 5 : Casting

The molten stainless steel is then cast into semi-finished forms, which can take the shape of plates, sheets, bars, or other forms. Continuous casting or ingot casting methods are usually employed for this purpose.

- Step 6 : Hot Rolling

In the case of products like stainless Steel Pipes, the semi-finished castings are hot-rolled to achieve the desired thickness and shape. During this process, the thickness of the castings is reduced while improving their mechanical properties.

- Step 7 : Cold Rolling and Annealing

In the case of specific stainless steel products such as thin sheets and coils, cold rolling is employed to further reduce the thickness and enhance surface finish. To relieve stresses and enhance corrosion resistance, annealing is frequently performed.

How do You Prevent Steel Pipes from Rusting?

- To maintain the structural integrity and prolong the lifespan of steel pipes, preventing rust is crucial. There exist various coatings and methods that can be employed to prevent rust in steel pipes.

- Galvanization is among the most efficient ways to prevent rust in steel pipes. It involves applying a layer of zinc on the surface of the steel, which creates a protective barrier. The zinc coating corrodes first before the underlying steel, providing long-lasting protection against rust. Steel Pipes that are galvanized are frequently utilized in water-related and outdoor applications.

- Coated To prevent rust formation, steel pipes can be coated with different substances that inhibit rust, such as polyethylene, epoxy, or polypropylene. These coatings create a shield between the steel and the environment, hindering moisture and oxygen from reaching the surface and causing rust.

- VCI (Volatile Corrosion Inhibitor) products release vapors that inhibit rust formation and protect steel surfaces from corrosion. They are frequently utilized to preserve steel pipes during transportation or storage.

Clients Project Report of Steel Pipe

Piping Project is a trusted Steel Pipe Manufacturers in Portugal. Our dedicated packing and shipping team ensures superior quality and precise dimensions of our products. Employing robust packaging methods that resist damage, we guarantee that our products reach their destination in excellent condition, upholding our commitment to delivering top-notch goods. We are also a well-known Steel Pipe Supplier in Portugal.

Client Projects of Steel Pipe

| Product supplied |

Countries |

| Steel Pipe Supply |

Lisbon |

| All types of Steel Pipe |

Porto |

| Steel Pipe Supplier |

Coimbra |

| Stainless Steel Pipe |

Braga |

Steel Pipe Used in Industries

- Steel Pipe Used in Construction

- Steel Pipe Used in Automotive Trim

- Steel Pipe Used in Stamped Machined Products

- Steel Pipe Used in Cookware

- Steel Pipe Used in Appliances

- Steel Pipe Used in Kitchen

- Steel Pipe Used in Sinks

- Steel Pipe Used in Railway Cars

- Steel Pipe Used in Foodservice Equipment

- Steel Pipe Used in Trailers

Steel Pipe Manufacturer & Supplier in Portugal

Steel Pipe Manufacturer in Portugal

Steel Pipe Supplier in

Portugal